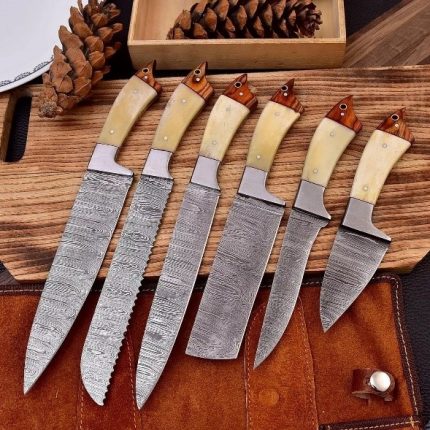

From the Forger:

Hand forged stainless steel set: In the first step of knife making, the craftsman uses a forging hammer and hand techniques to heat a raw block of steel to the proper temperature and, through repeated fine hammering, shape the steel into the initial shape of the knife. This process requires an experienced craftsman and an in-depth understanding of metal properties.

High-heat treatment: During manufacturing, knives undergo high-temperature treatments, usually quenching and tempering. First, the tool is quenched to cool it quickly to increase its hardness. Then it is tempered to reduce internal stresses and increase toughness by controlling the heating temperature and time to ensure that the tool is less likely to break in use.

Repeated forging and tempering: To achieve higher strength and better flexibility, our craftsmen repeatedly forge and temper. This process, designed to further improve the lattice structure of the steel and adjust its properties, ensures that our knives are not only durable but also maintain their sharpness over time, providing a long-lasting and reliable tool in your kitchen.

Fine cutting edge: The final step is to finely carve and polish the blade. At this stage, our craftsmen use a variety of sharpening tools, including grinding wheels and whetstones, to polish and sharpen the blades to ensure that they have an exceptional level of sharpness and smoothness. This guarantees optimal cutting results and a thrilling cooking experience when using our knives.

Reviews

There are no reviews yet.