From the Forger

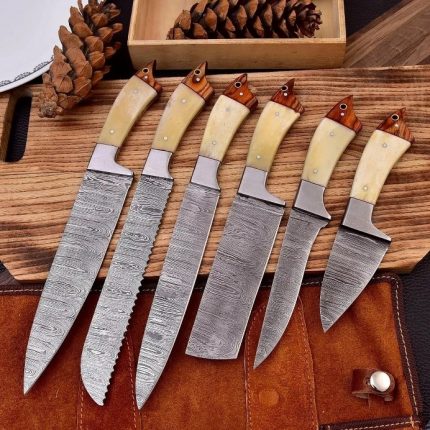

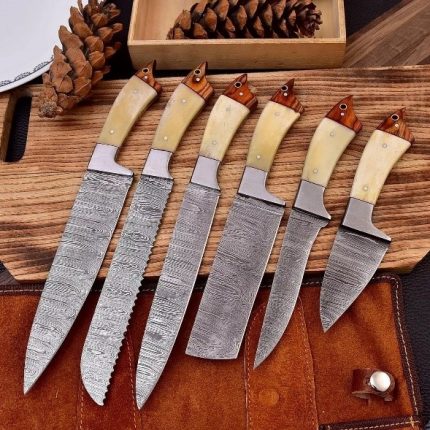

Our Damascus Steel Creation Process:

Our workshop is home to skilled craftsmen who take immense pride in their work, crafting authentic Damascus steel knives that surpass mere acid etching. Here’s an overview of our Damascus steel-making process:

1. Material Selection: We meticulously combine 1095HC and 15N20 nickel carbon steel for our blades.

2. Layering: The chosen steels undergo repeated heating and folding to achieve a remarkable 384 layers.

3. Acid Burn: Following the layering process, the blade is treated with acid, revealing the brilliant nickel shine and a dark gray hue in the high-carbon steel and showcasing the stunning Damascus patterns.

4. Blade Finishing: We expertly sharpen the blade’s edge concurrently, transforming the acid-treated edge into a striking satin finish.

Our unwavering commitment to preserving the authenticity and craftsmanship of Damascus steel ensures that each knife in our collection showcases intricate layers and delivers exceptional performance.

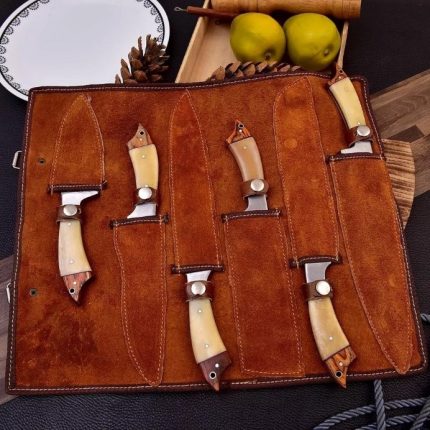

Hardwood Handle with Brass Pins, Mosaic Pins

Blade Material: 1095 HC and 15N20 With Nickle Carbon Damascus Steel

Blade Hardness: 54-58 HRC

Reviews

There are no reviews yet.